Maersk Triple-E – Biggest Ship in the World

Sep 11 2011

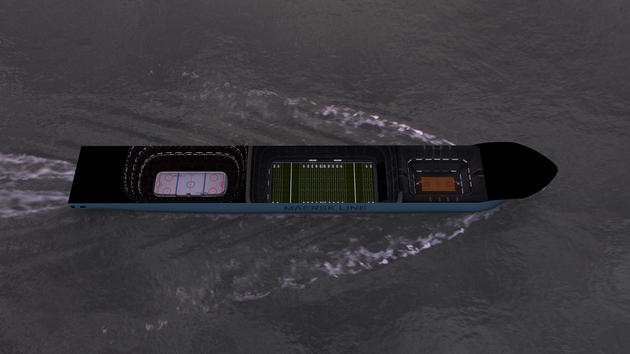

The construction of ten Triple-E vessels, each capable of carrying 18,000 twenty foot containers, will put Maersk Line at the helm of change. The size and capacity of these vessels, at 400 metres long and 59 metres wide, will help reduce energy consumption and lower CO2 emissions.

Note: The largest ship to sail our waters was actually an oil tanker by the name of Seawise Giant, however it was decommissioned in 2009. More info can be found here: http://en.wikipedia.org/wiki/Seawise_Giant

Quick Facts:

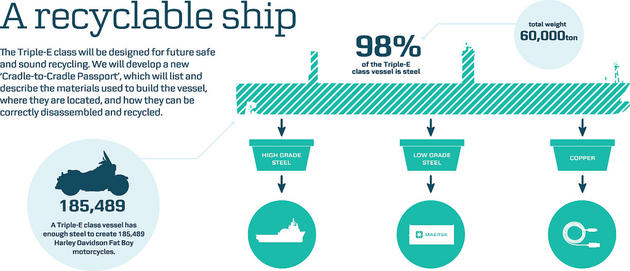

- At 60,000 tons, Triple-E has the same amount of steel as 8.4 Eiffel Towers.

- The vessel has enough steel to build 185,489 Harley Davidson motorcycles.

- A Triple-E class vessel is equipped with a waste heat recovery system, saving up to 10% of main engine power. This equals the average annual electrical consumption of 5,000 European households.

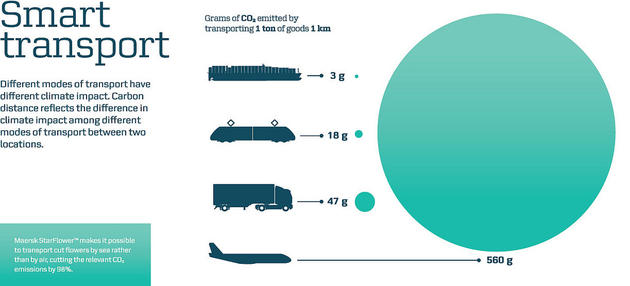

- The Triple-E class travels 184 kilometers using 1 kWh of energy per ton of cargo, whereas a jumbo jet travels half a kilometer using the same amount of energy per ton of cargo.

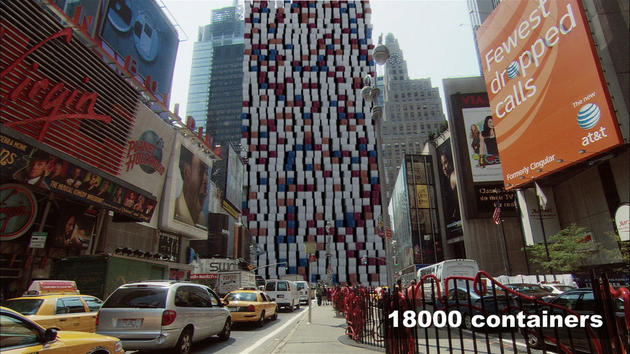

- The vessel can carry 18,000 twenty-foot-equivalent units (TEU). If all these containers were to be put on a train - it would need to be 110 km long - and if they were put on top of each other they would almost reach beyond the stratosphere (47 km).

A clear trend in cargo patterns reveals the rapid growth of East and North China markets, which will shift cargo further north. This will lead to a change in vessel requirements and shipping patterns. This shift presents Maersk with the opportunity to build more energy efficient vessels and lead the industry in a new and more environmentally friendly direction.

The ten Triple-E class vessels — standing for Economy of scale, Energy efficiency, and Environmentally improved — are to be built by Korea's Daewoo Shipbuilding and Marine Engineering Co. Ltd. in accordance with standards of the classification society ABS. Deliveries are scheduled for 2013-2015, and Maersk Line has an option to order an additional twenty vessels. The vessels will be built for Asia-Europe trade.

Changing the World of International Shipping

The Triple-E’s enormous capacity can move the greatest number of containers possible in the most efficient way and with the smallest CO2 footprint. And combined with an energy saving propulsion system, its size is a major factor in its industry best energy efficiency and performance.

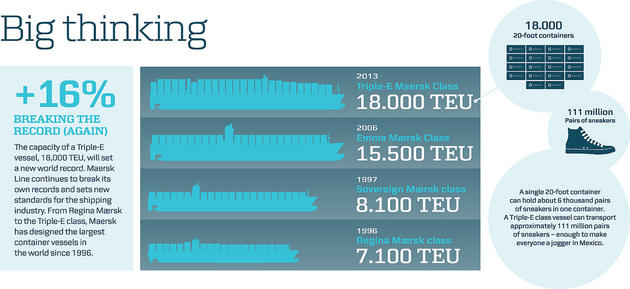

The Triple-E is a giant. At 400 meters in length and with a capacity for 18,000 twenty-foot containers (TEU), it is the new benchmark for size in the shipping industry. Through feats of innovative engineering, the Triple-E’s vastly expanded inside cavity gives it a capacity 16 percent greater than Emma Maersk (equivalent to 2,500 containers), despite relatively little change in the length and width.

But the Triple-E isn’t just the largest vessel of any kind in operation today: it is actually the longest and widest container vessel possible based on port restrictions. And the reality is that the visible dimensions of the ship–only four meters longer and three meters wider than Emma Mærsk, the world’s largest vessel in operation– do not fully convey its size.

Container capacity and energy efficiency are the two main drivers behind the design of the Triple-E. To improve upon the design of Emma Mærsk, the current benchmark in both of those categories for all vessel types, a different set of performance parameters was established.

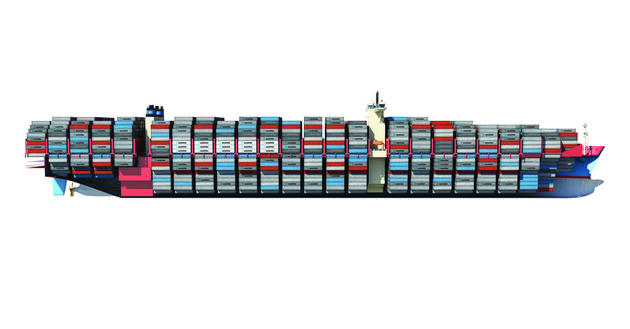

The Shape of Change

Container capacity is the top priority. Because of that, a wider hull is essential. The V-shaped hull of Emma Mærsk is sleek and limits resistance in the water, but also limits space for containers towards the bottom of the ‘V’. Therefore, the Triple-E boasts a more U-like hull form. An additional row of containers was added to the Triple-E as well, giving it 23 rows across its width, compared to Emma’s 22. The more spacious hull and extra row hereby provide additional capacity for 1,500 containers.

Additional container space has been created in the vessel by moving the navigation bridge and accommodation 5 bays forward and the engine room and chimney 6 bays back in what is called a ‘two-island’ design. With the more forward navigation bridge, containers can be stacked higher in front of the bridge (approximately 250 more) without losing visibility. And approximately 750 more containers fill the space behind the bridge above deck and below deck using the space created by the engine room’s position further to the back of the vessel.

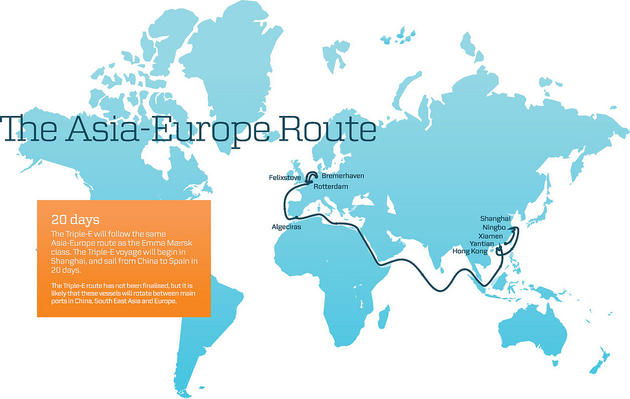

Europe-Asia Route

The Triple-E would not exist without the remarkable economic growth of China. And as the world’s second largest economy continues its booming growth, the Triple-E will position Maersk Line to meet that growth in the most efficient way possible.

For Maersk Line, this gradual change is reflected in the growing number of services covering Asian ports as well as the significant share of those services that connect China in particular to the rest of the world.

Currently, Maersk Line has the largest market share of any container shipping line in this trade, moving 18 percent of the container cargo leaving Asia for Europe and 15 percent of the container cargo traveling from Europe to Asia.

The Triple-E vessels will touch five Chinese ports (Shanghai, Ning-bo, Xiamen, Yantian and Hong Kong) adding significant capacity to the vessel strings serving Asia - Europe and furthering Maersk Line’s dominance in the trade.

The vessel’s dramatically improved efficiency will also help limit the environmental impact of the region’s continued economic growth.

Energy Efficient Innovation

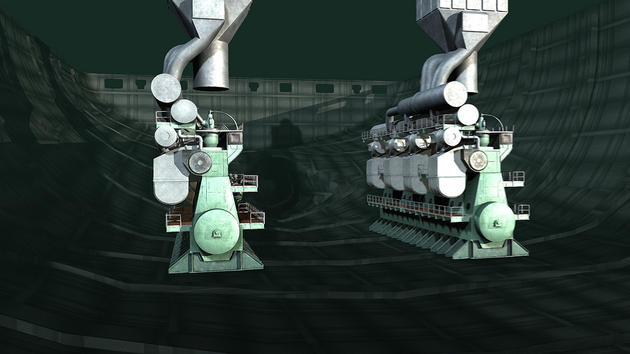

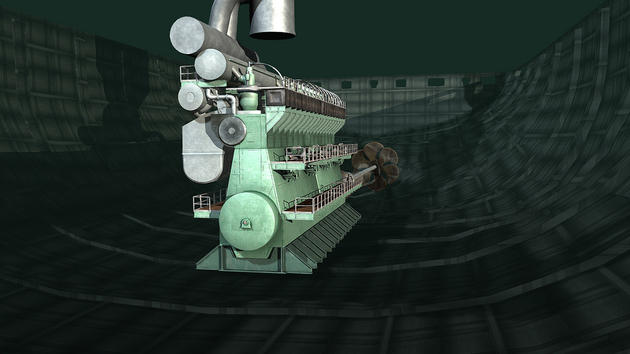

The world’s largest container vessel does not require a gas-guzzling monster in its engine room to move it through the water. In fact, the Triple-E’s ‘twin skeg’ propulsion system (two-engine, two- propeller) is central to the vessel’s world record energy efficiency.

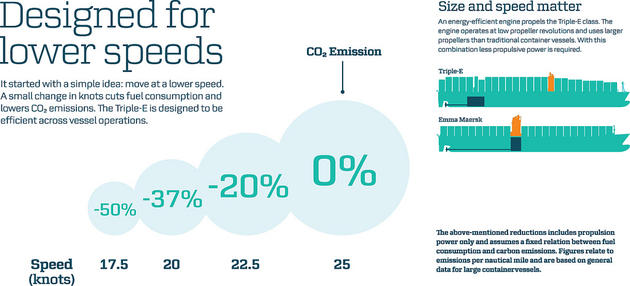

To achieve the huge improvement in energy efficiency boasted by the Triple-E, its design is optimized to sail with the maximum possible cargo load at the speeds that the industry practices today, while at the same time reducing the impact on the environment.

Innovations in technology and engineering, such as two ‘ultra-long stroke’ engines, and specially optimized hull and bow forms allow the Triple-E to lead the way in energy efficiency. An advanced waste heat recovery system captures and reuses energy from the engines’ exhaust gas for extra propulsion with less fuel consumption.

Energy Efficient Propulsion System

To build the world’s largest and most efficient vessel, Maersk Line needed to custom design a propulsion system that would be both powerful enough to move the vessel, but with maximum energy efficiency.

The top speed of the Triple-E was capped at 23 knots, two knots lower than Emma Mærsk’s top speed. This meant a power requirement of only 65-70 megawatts compared to Emma’s 80 megawatts – a 19 percent reduction.

A slower max speed also enabled Maersk Line to consider engines that could operate at slower revolutions – ‘ultra-long stroke’–, which provides the greatest energy efficiency. To retain the efficiency created by the slower revolutions of an ultra-long stroke engine requires a larger propeller diameter. However, the dimensions of the vessel and the available space beneath the keel limit the size of the propeller.

To mitigate these restrictions and achieve the desired efficiency, Maersk Line research determined that a two engine/two propeller ‘twin skeg’ system was superior to the one engine/propeller setup.

All together, the Triple-E’s twin-skeg propulsion system consumes approximately 4 percent less energy than Emma Mærsk’s single engine/single propeller propulsion system.

An Innovative, Efficient Shape

The new Triple-E vessel is designed with a wider hull and more bulbous bow to accommodate a capacity for 18,000 twenty-foot containers and the lower operational sweet spot of the vessel’s propulsion system.

The Triple-E’s bulkier hull combined with a more bulbous bow creates more resistance in the water than Emma Maersk’s sleeker V-shape, which would typically be less desirable – but not in this case. The Triple-E’s dual engine is limited to a top speed of 23 knots and can run as low as 80 revolutions per minute (rpm), compared to Emma’s 25 knots and 90 rpm.

This means the Triple-E’s operational sweet spot – the speed at which the vessel is most energy efficient – is lower than Emma’s, meaning the increased resistance caused by the bulkier design has no significant impact on the Triple-E’s greater overall efficiency.

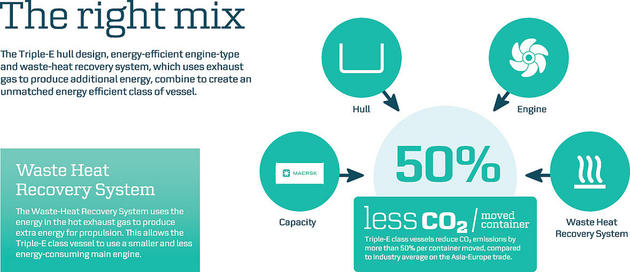

Energy Efficient Waste Heat Recovery System

The Triple-E is the latest in a long succession of Maersk Line vessels, including the Emma Mærsk class of vessels, to be equipped with an energy saving advanced waste heat recovery system.

The purpose of the waste heat recovery system is simple: to reduce the engine’s need for fuel and therefore its CO2 footprint.

Instead of being transferred to the propellers, approximately 25 percent of the energy contained in a vessel’s fuel is lost when the engine’s hot exhaust gas escapes into the atmosphere. But with a waste heat recovery system, the heat and pressure contained in the exhaust gas is captured and used to move turbines creating mechanical energy that operates an electrical generator.

For the Triple-E, the effect of the waste heat recovery system is a reduction in the engine’s fuel consumption and CO2 emissions by approximately 9 percent.

A sustainable Development

The Triple-E will produce 20 percent less CO2 per container moved compared to Emma Mærsk, and 50 percent less than the industry average on the Asia-Europe trade lane. At Maersk Line, sustainable development drives innovation and change on the water.

Cradle to Cradle

Maersk Line’s Triple-E vessel will set a new standard for sustainable shipbuilding and recycling by introducing the most comprehensive material documentation system the shipping industry has ever seen.

To eliminate waste and ensure the safest and most efficient handling of the ship’s materials once it is removed from service, each Triple-E vessel will come with a ‘cradle-to-cradle passport’. This will be a living document, describing the material composition of every piece of the ship.

The term cradle-to-cradle refers to the optimal life-cycle of the materials in a product: specifically that they should either biodegrade and be absorbed back into nature or be recycled. Not wasted.

Maersk Line worked with the Environmental Protection Encouragement Agency (EPEA), a German organization that specializes in the cradle-to-cradle concept, to develop the idea for its passport.

Maersk Line already has a Green Ship Recycling Unit, which has worked with a shipyard in China to safely recover and dispose of hazardous materials on more than 50 vessels in the last decade. With the cradle-to-cradle passport Maersk Line is dramatically expanding the scope of that effort from safe and effective recycling of hazardous materials to recycling and reuse of all materials.

Reducing CO2 Emissions

Its size is remarkable, but the most impressive and important attributes of the Triple-E cannot actually be seen. The Triple-E class of container vessels will emit 20 percent less carbon dioxide per container moved compared to the most efficient container vessel operating today and 50 percent less than the industry average for vessels operating on the Asia - Europe trade.

Maersk Line has committed to reduce its CO2 emissions per container moved by 25 percent by 2020 (compared to 2007 CO2 emission levels.) So far, and not including the progress made with Triple-E, the company has reduced its CO2 emissions by 14 percent. The Triple-E will be a key component in reaching this first goal.

With room for 18,000 TEU (twenty-foot containers), the Triple-E has a capacity for 2,500 more containers than Emma Mærsk, meaning less carbon dioxide emitted per container moved. And despite its size, the Triple-E is no gas guzzler: the vessels use approximately 35 percent less fuel per container moved than the 13,100 TEU ships being delivered to other container shipping lines in the next few years for service on international shipping, especially the Asia - Europe trade.

An Energy Efficient Combination

One major reason for its superior energy efficiency is what is happening in the Triple-E’s engine room. The Triple-E is designed for a top speed of 23 knots, compared to Emma Mærsk’s top speed of 25 knots. That tiny difference in maximum speed lowers the power output needed from the engine by 19 percent, which allows for slower revolutions in its engines and far greater fuel economy.

The Triple-E has two slow running engines (‘ultra-long stroke’) and two large propellers, a combination called ‘twin skeg’. The reason for using this combination is that Maersk Line studies found that using two of these slower running engines to turn two propellers results in further energy savings of 4 percent compared to a one engine/one propeller design.

Boosting the energy efficiency of the vessel further is a waste heat recovery system situated in the engine room that captures and reuses heat and pressure from the engine’s exhaust that would normally escape as wasted energy. Reusing this waste heat increases the power to the engine by 9 percent, reducing fuel consumption by 9 percent.